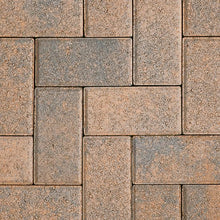

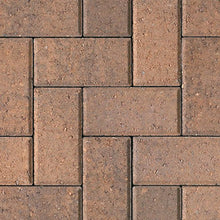

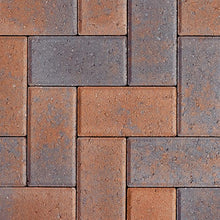

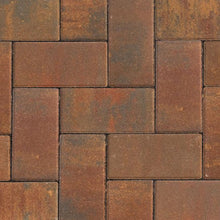

Hollandstone Series

Sold By The Sq Ft

Hollandstone Classic is available in 4 Colors: Terra Cotta, Rustic Red, Sandstone, Beechwood

Hollandstone Premier is available in 4 Colors: Granite, Charcoal, Ivory and Fossil

SHAPE AND SIZE

3 7/8" x 7 7/8" x 2 3/8"

106.40 Sq Ft Per Pallet

RECOMMENDED BASE STABILIZATION – one layer of DriveGrid™" stabilization grid between subgrade and base material. Recommended depth 8” to 10” below pavers for maximum stability and performance. Use under Standard Base or Permeable Base.

STANDARD BASE – Min. 6” – 8” of ¾” Crusher Run gravel (any road base standard in accordance with ASTM-D2940) compacted to 98% Standard Proctor Density (SPD).

STANDARD BEDDING COURSE – 1” thick of coarse sand– in accordance with ASTM-D2940 screeded over base.

ALTERNATIVE PERMEABLE BASE – Min. 6” – 8” of ¾“ clear open-graded stone compacted to achieve full particle lock-up and consolidation. (Clear open-graded does not compact but does consolidate slightly by rattling the particles together.)

ALTERNATIVE PERMEABLE BEDDING COURSE – 1” thick of 1/4” clear open-graded chip stone – (ASTM No. 8) screeded over base.

SPECIAL NOTE: CONCRETE DIRECT OVERLAY – In some areas of the country and in some applications pavers are very successfully placed directly over concrete. Concrete as a base is in itself quite strong, but it can affect the structural integrity of the paver particularly in vehicular applications, where the concrete below is sub-par. The following considerations must be taken into account to insure that the concrete below the surface is ideal:

- Concrete integrity – concrete must be in good condition, and not crumbling

- Drainage slope – concrete below must be sloped away from all buildings and structures

- Drainage holes – In lowest areas of the concrete, drill 1” holes in concrete (on 12” centers) and fill holes with ¼” chip (ASTM No. 8)

- Base drainage - the area below the concrete must not be subject to frost movement

- Surface - surface must be totally smooth and flat equivalent to the desired finished surface

- Waterproofing - may be required when installing pavers over concrete where there is a basement or cold cellar below. Install an impervious rubber membrane over the surface prior to installing any pavers over the surface.

- Jointing Sand - Use an impervious polymeric sand when installing over concrete